Why Speed Construction Is No Longer Optional in India — And Why Chennai Is Leading the Shift

Introduction: The End of “Normal” Construction Timelines

For decades, Indian construction has accepted delays, cost overruns, labour dependency, and quality variation as normal. Projects slipping by months — sometimes years — have been treated as an operational inconvenience rather than a structural failure.

That era is ending.

Across housing, industrial, infrastructure, and institutional projects, speed of delivery has become a strategic requirement, not a competitive advantage. Capital costs are rising. Labour availability is shrinking. Project financing is becoming stricter. Asset monetisation cycles are tightening.

In this environment, speed construction is no longer optional — it is the only viable path forward.

And nowhere is this shift more visible, practical, and scalable than in South India — with Chennai emerging as the epicentre.

What Speed Construction Really Means (And What It Does Not)

Speed construction is often misunderstood.

It does not mean:

-

Cutting corners

-

Reducing specifications

-

Compromising structural integrity

-

Rushing site activities

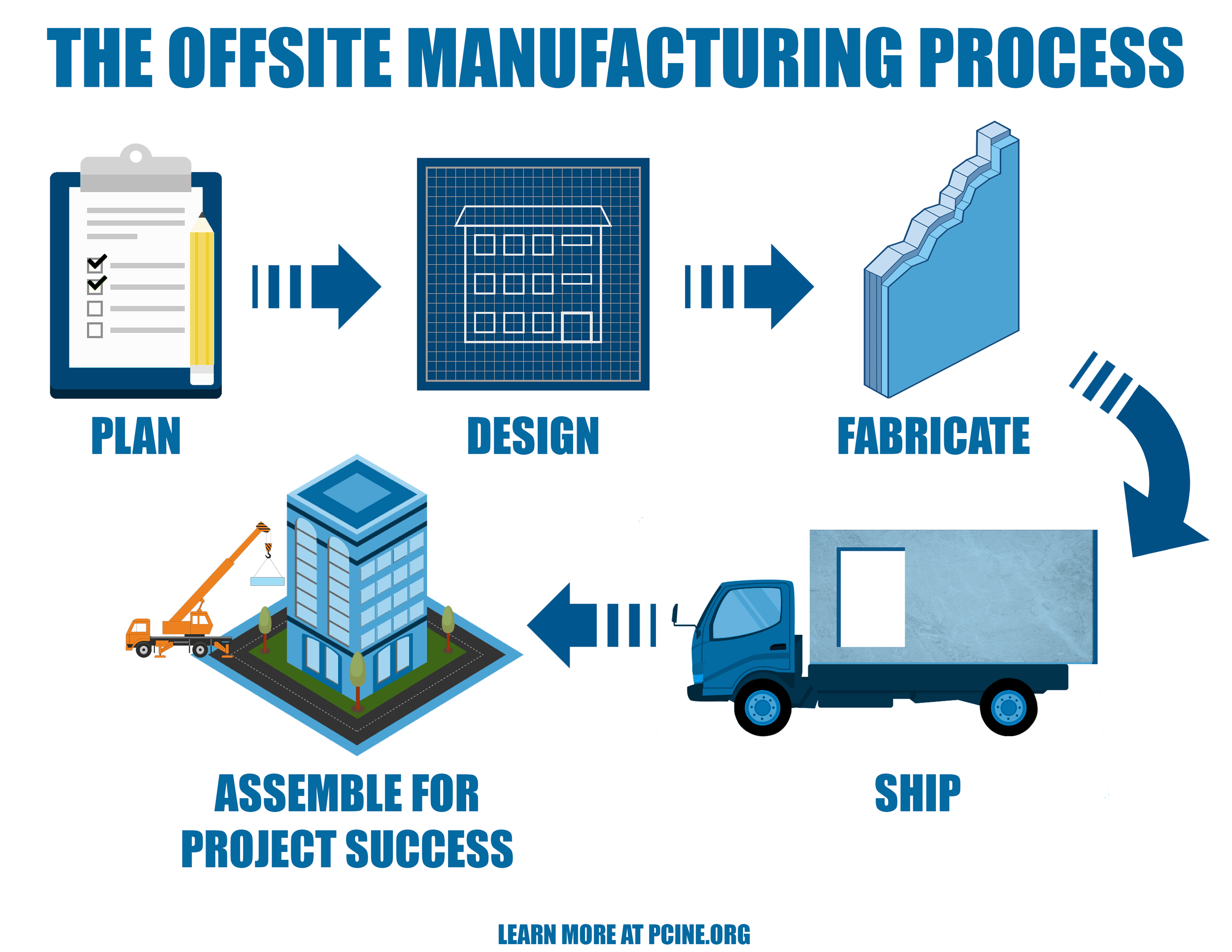

True speed construction is the outcome of system-led building, where time savings are engineered before construction begins.

At its core, speed construction is driven by:

-

Off-site manufacturing

-

Parallel workflows

-

Standardized systems

-

Predictable execution

-

Controlled environments

This is precisely where prefab and precast construction move from being “alternative methods” to becoming default solutions.

The Structural Forces Making Speed Construction Inevitable

1. Capital Is No Longer Patient

Every month of delay today directly impacts:

-

Interest during construction

-

Opportunity cost of locked capital

-

Revenue realization timelines

-

Investor confidence

For developers and industrial investors, time is now a balance-sheet variable.

Prefab and precast systems compress timelines by 30–60%, not by working faster on site, but by removing site dependency altogether.

2. Labour Risk Has Become Systemic

Indian construction is facing:

-

Skilled labour shortages

-

High attrition

-

Migration volatility

-

Productivity inconsistency

Speed construction reduces on-site labour dependency by shifting work into factory-controlled environments, where:

-

Productivity is predictable

-

Quality is measurable

-

Safety is enforceable

This is not an efficiency upgrade — it is a risk mitigation strategy.

3. Project Complexity Has Outgrown Traditional Methods

Modern projects demand:

-

Faster commissioning

-

Tighter tolerances

-

Integrated MEP systems

-

Repeatable quality across locations

Traditional construction methods were not designed for this level of complexity at scale. Prefab and precast are.

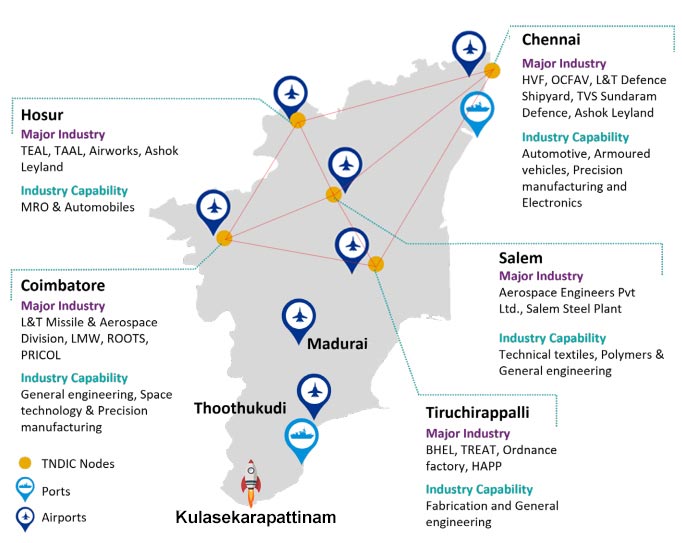

Why Chennai Is Emerging as India’s Speed Construction Capital

Chennai is not leading this shift by accident. It sits at the intersection of policy, industry, infrastructure, and execution capability.

1. Industrial Density and Repeatable Demand

Tamil Nadu has one of India’s highest concentrations of:

-

Manufacturing plants

-

Industrial corridors

-

Warehousing clusters

-

Automotive and electronics ecosystems

These projects demand:

-

Fast delivery

-

Standardised layouts

-

Predictable costs

-

Minimal downtime

Prefab and precast naturally align with this demand profile.

2. Execution-Driven Market Culture

South Indian construction markets — particularly Chennai — are:

-

Execution-oriented

-

Cost-sensitive

-

Timeline-focused

This creates fertile ground for system adoption, not just technology curiosity.

3. Strong Ecosystem of Fabricators and System Providers

Unlike regions that depend on imported solutions, South India has developed:

-

Precast yards

-

Steel fabrication capacity

-

Modular manufacturers

-

Logistics and erection expertise

This ecosystem maturity enables real adoption, not pilot projects.

Speed Construction Is a System, Not a Product

One of the biggest failures in the Indian construction discourse has been treating prefab and precast as products. They are not. They are systems.

A speed construction system integrates:

-

Structural design

-

Manufacturing logic

-

Transportation planning

-

Erection methodology

-

Jointing and tolerances

-

Finishing interfaces

-

MEP coordination

When any one of these is missing, speed collapses.

This is why:

-

Isolated product exhibitions fail to deliver value

-

Buyers struggle to connect components into outcomes

-

Adoption remains fragmented

The industry does not need more products. It needs execution-ready systems.

The Investor Perspective: Speed as a Risk-Control Tool

From an investor’s lens, speed construction delivers three non-negotiables:

1. Cost Certainty

Factory-controlled production reduces:

-

Material wastage

-

Rework

-

Variation orders

-

Delay-linked escalation

2. Timeline Predictability

Parallel processing (manufacturing + site prep) removes sequential dependencies.

3. Asset Monetization Acceleration

Earlier completion means:

-

Faster leasing

-

Faster production start

-

Faster revenue generation

Speed construction is no longer a technical decision. It is a capital allocation decision.

Why the Industry Needs a New Kind of Platform

Despite the clear shift, the industry still lacks a serious, execution-focused platform where:

-

Systems are presented holistically

-

Buyers are decision-makers

-

Conversations move beyond brochures

-

Outcomes matter more than footfall

Generic construction exhibitions are not designed for this role.

They are built for volume, not velocity.

What the industry needs is:

-

Curation, not crowding

-

Systems, not stalls

-

Execution, not exhibition

Our Role: Curating the Speed Construction Ecosystem

This is where the Prefab & Precast Construction Expo – Chennai positions itself fundamentally differently.

The intent is not to create another event.

The intent is to curate the speed construction ecosystem.

As curators, the responsibility is to:

-

Define what qualifies as a system

-

Filter exhibitors based on execution capability

-

Attract buyers with live or upcoming projects

-

Eliminate irrelevant noise

-

Protect technical integrity

This is not neutrality.

This is industry stewardship.

Why Participation Is No Longer Optional

For system providers, EPCs, and solution leaders, the question is no longer whether speed construction will dominate — but who will define its standards.

Participation in a curated, execution-focused platform is about:

-

Visibility among serious buyers

-

Positioning as a system leader

-

Influencing how the market understands speed construction

-

Being present where decisions are made

In emerging categories, absence is invisibility.

Conclusion: The Shift Has Already Begun

Speed construction is not a future trend.

It is a present reality.

Chennai is not experimenting.

It is executing.

Prefab and precast are not alternatives.

They are becoming defaults.

The only remaining question for the industry is:

Who is ready to move from products to systems, from delay tolerance to delivery discipline, and from exhibitions to execution platforms?

The answer to that question will define the next decade of Indian construction.