The Hidden Problem Nobody Wants to Name

Indian construction has never lacked products.

Cement, steel, formwork, panels, admixtures, facades, roofing systems — the market is saturated with options. Yet projects continue to suffer from delays, coordination failures, cost overruns, and execution risk.

The problem is not availability. The problem is fragmentation.

For decades, the industry has attempted to build complex assets using isolated products stitched together on-site, expecting speed, quality, and predictability as outcomes. That model has reached its structural limit.

What is replacing it is not a new material or a new technology — but a fundamental shift in thinking:

From products → to building systems

This shift is redefining how buildings are designed, manufactured, executed, financed, and delivered.

Why the Product-Centric Model Is Breaking Down

Traditional construction follows a linear, product-led workflow:

-

Design is completed in silos

-

Products are specified independently

-

Vendors are selected individually

-

Integration is attempted on-site

This approach assumes the site can absorb complexity. That assumption is no longer valid.

Structural Limitations of Product-Led Construction

-

High dependency on site labour skill

-

Interface clashes between trades

-

Sequential execution (one delay cascades)

-

Unpredictable tolerances

-

Rework and variation orders

-

Poor accountability for outcomes

As projects scale faster and capital tightens, these inefficiencies compound. The result: risk is pushed downstream, where it is most expensive to manage.

What Exactly Is a “Building System”?

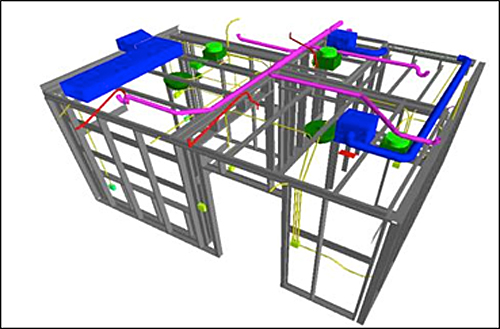

It is a pre-engineered, execution-ready methodology that integrates:

-

Structural logic

-

Manufacturing constraints

-

Transportation limits

-

Erection sequencing

-

Jointing and tolerances

-

Finishing interfaces

-

MEP coordination

A true system answers one question completely:

“How does this building get delivered — end to end?”

If that answer is incomplete, it is not a system.

Why Prefab & Precast Are System Technologies by Nature

Prefab and precast are often discussed as construction methods.

In reality, they are system technologies.

They demand:

-

Design for manufacture (DfM)

-

Design for assembly (DfA)

-

Early-stage coordination

-

Fixed tolerances

-

Standardised interfaces

-

Parallel workflows

These requirements force discipline upstream, where problems are cheapest to solve. This is why prefab and precast succeed where traditional methods struggle — not because they are faster on site, but because they eliminate site improvisation.

The Shift from Site-Centric to Factory-Centric Construction

In system-led construction, the center of gravity moves:

| Traditional Model | System Model |

|---|---|

| Site | Factory |

| Labour-driven | Process-driven |

| Reactive | Predictive |

| Sequential | Parallel |

| Variable outcomes | Repeatable outcomes |

This shift transforms construction from a craft-based activity into an industrial process.

And industrial processes demand systems — not products.

Why Investors and Developers Are Demanding Systems

From a capital perspective, systems deliver three things products never can:

1. Predictability

Systems behave consistently across projects, locations, and timelines.

2. Accountability

A system provider owns performance, not just supply.

3. Scalability

Once proven, systems can be replicated without reinventing execution every time.

This is why global capital increasingly prefers:

-

Platform builders over contractors

-

System integrators over product vendors

-

Predictable returns over theoretical margins

The Industry’s Mistake: Exhibiting Products Instead of Outcomes

Most construction exhibitions are organized around product categories:

-

Cement

-

Steel

-

Chemicals

-

Panels

-

Equipment

While informative, this format reflects how the industry sells, not how projects are delivered.

Buyers, however, think differently:

-

“How fast can I build?”

-

“What will it cost me end-to-end?”

-

“Who takes execution responsibility?”

-

“What risks are eliminated?”

Product exhibitions rarely answer these questions. This disconnect is one of the biggest barriers to prefab & precast adoption.

Why System-Led Curation Matters

Curation is not about limiting participation.

It is about protecting coherence.

A system-led platform must:

-

Filter exhibitors based on execution capability

-

Reject standalone products that cannot integrate

-

Group solutions by building typology

-

Encourage outcome-based conversations

-

Attract buyers with real projects, not curiosity

Without curation, systems dissolve back into products.

Our Role as Curators: Defining the System Standard

The Prefab & Precast Construction Expo – Chennai is built on a single organising principle:

If it cannot be delivered as a system, it does not belong here.

This is a deliberate departure from traditional exhibitions.

As curators, the role is to:

-

Set minimum system criteria

-

Demand execution references

-

Encourage transparency on timelines and costs

-

Align exhibitors around delivery, not display

-

Create an environment where outcomes matter

This is not exclusion.

It is industry discipline.

Why This Shift Will Define the Next Decade

Construction is moving toward:

-

Fewer vendors

-

Stronger integrators

-

Standardised delivery models

-

Factory-backed execution

-

Capital-aligned timelines

Those who continue to operate as product sellers will struggle to remain relevant. Those who evolve into system providers will define the future. Platforms that recognize and reinforce this shift early will become benchmarks.

Conclusion: Systems Are the New Language of Construction

The question is no longer: – “What product do you sell?”

It is:

“What system do you deliver?”

Prefab and precast are accelerating this transition — not as alternatives, but as enablers of a new construction logic.

The Prefab & Precast Construction Expo – Chennai exists to reflect, organize, and advance this shift.

Not by showcasing more products —but by curating systems that actually build buildings.